- SoMachine To Citect Studio:

- Create the PLC Tags in SoMachine as Global Variables(GVL).

- Create Symbol Configuration and click the Check box in GVL to access.

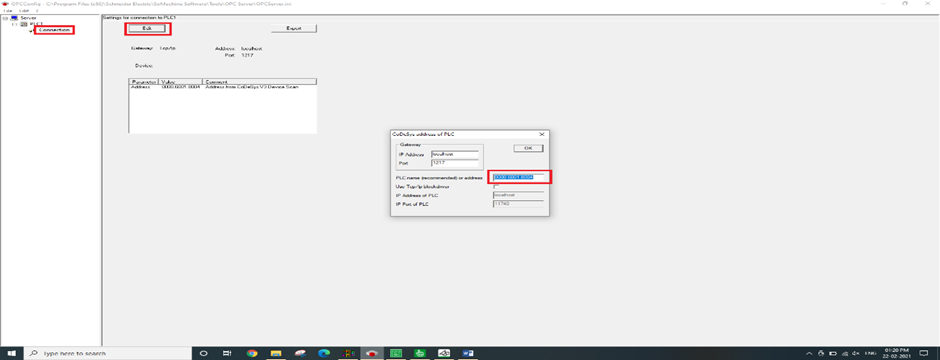

- Open OPC Server.

- Right Click Server –>Append PLC –>Click Connection –>Edit.

- Enter the PLC Name as per the SoMachine Software.

- Check the PLC Name in SoMachine –>Tools –>OPC –>CoDeSys PLC Address.

- Then save OPC Configuration.

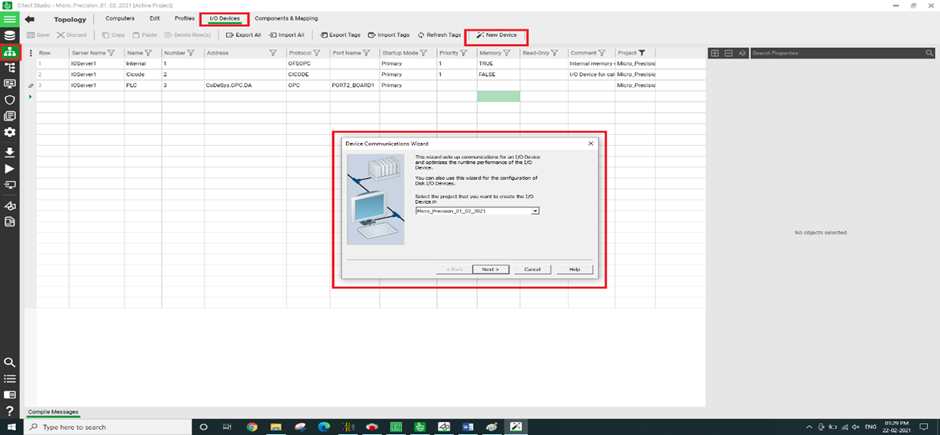

In Citect Studio:

- Open Citect Studio –>Topology –>I/O Devices –>New Device .

- Device Communication Wizard Popup Will display –>Create I/O Server –>Next

–>Create a new I/O Device–>Next –>Slecet the type of I/O Device –>Next –>Select OPC Fountation –>OPC DA Client –>OPC–>Next–>Enter the address(CoDeSys.OPC.DA)–>Next–>Click the Checkbox in the Link I/O Device to an external tag database–>Database type–>Select OPC–>External Tag Database–>OPC Data Access Server Parameter Popup Will Display–>Select CoDeSys.OPC.DA–>PLC(This is the PLC name Created in OPC server)–>OK–>Next–>Finish.

- Now the PLC Tags will connect with SCADA

- Cilck Refresh Tags for further tags added in SoMachine Software.

What is Core Industry?

Generally, when I’m doing interview with engineers they mostly using this word core industry. “I don’t like software industry; I would like to work in the core industry”.

From that I can understand one thing is, people thinking that jobs segregated in 2 way

1. Software

2. Core

What is core industry in engineers mind commonly???

hardware/manufacturing or civil mechanical electrical electronics etc…

Is it right?

Not exactly.

Then what is core industry?

Core industries can be defined as main or key industries of the economy. In most countries, these particular industries are backbone of all other industries. In India, there are eight core sectors comprising of coal, crude oil, natural gas, petroleum refinery products, fertilizers, steel, cement and electricity. The eight infrastructure sectors constitute 40.27% of the total index of industrial production (IIP)

Reference: ........ currentaffairs.gktoday.in/tags/core-industries © GKToday

Now we can discuss the topic. Industry classified as

1. Manufacturing industry – producing goods – car mobile food cloths TV etc…

2. Service industry – Provide service either directly or indirectly to the manufacturing industry – Software banking customer care etc…

So job also defined in the same way. That is any engineer can get or work in the manufacturing side or service side.

Suppose you are an electrical engineer you can work as a production engineer, maintenance engineer, design engineer, sale engineer or marketing engineer Etc.., in the company.

In the above set of job we are going to apply our knowledge and doing work. Engineers come under skilled. Now a day we are using software in all areas. That means software is not a separate area to do work. It is also a part of service, related to manufacturing.

Manufacturing is the process to produce the product or goods were the service is nothing planning, design, procedure and support (data or document to do manufacturing).

Here after we can’t say software not related to my study, any engineer can be a software engineer. Software is the tool to do work, design, plane, database and forecasting etc...

Auto CAD is the software electrical engineer can design electrical concept like panel and circuit designing.

Mechanical engineer can design the manufacturing plan, structural plan and many.

Software giving plan for the manufacturing industry, SAP ERP etc…

You can ask one question, then what is role of CSE and IT, they develop this all applications Auto CAD, SAP, ERP, MS office, VB, C, C++, Java etc…

One thing I can say, I have to say…

Choosing the job is related to your interest, skill and what you are studied…..

Electrical engineer should be an electrical engineer….

- Download DTM Soft from DELTA download center.

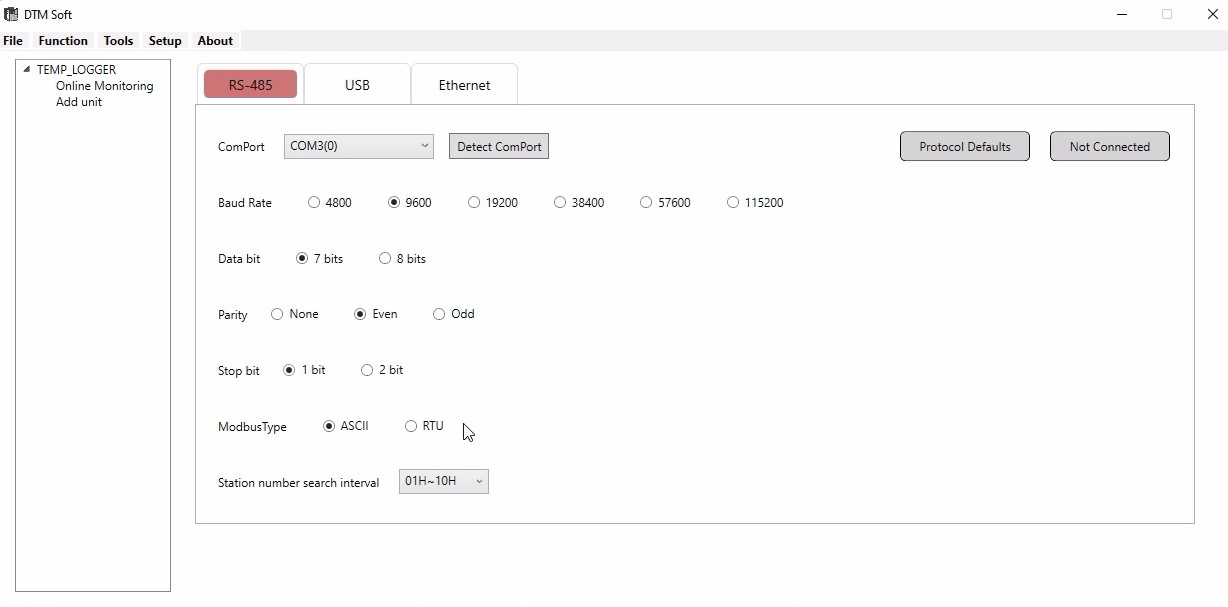

- Open DTM Soft,click New project,give Project name and save.

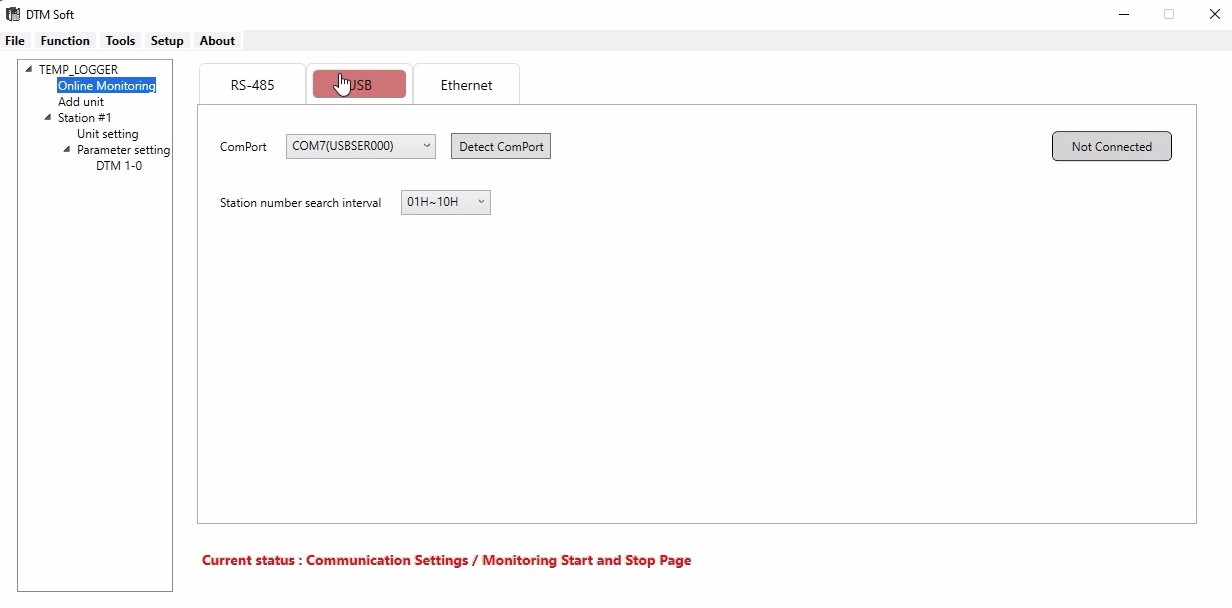

- A new window opens for the DTM Soft,click on RS 485,give com port.

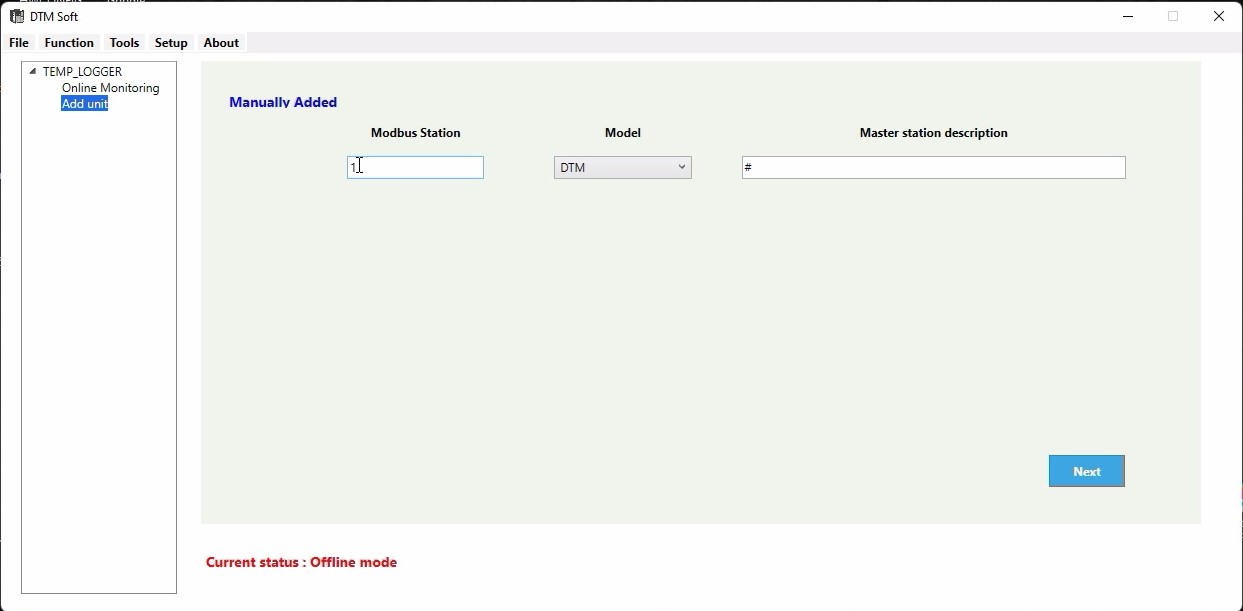

- Click Add unit on the left side,Assign modbus station number and model name,then click next.

- After giving next,a Parameter setting option will be displayed at the left side of the screen.

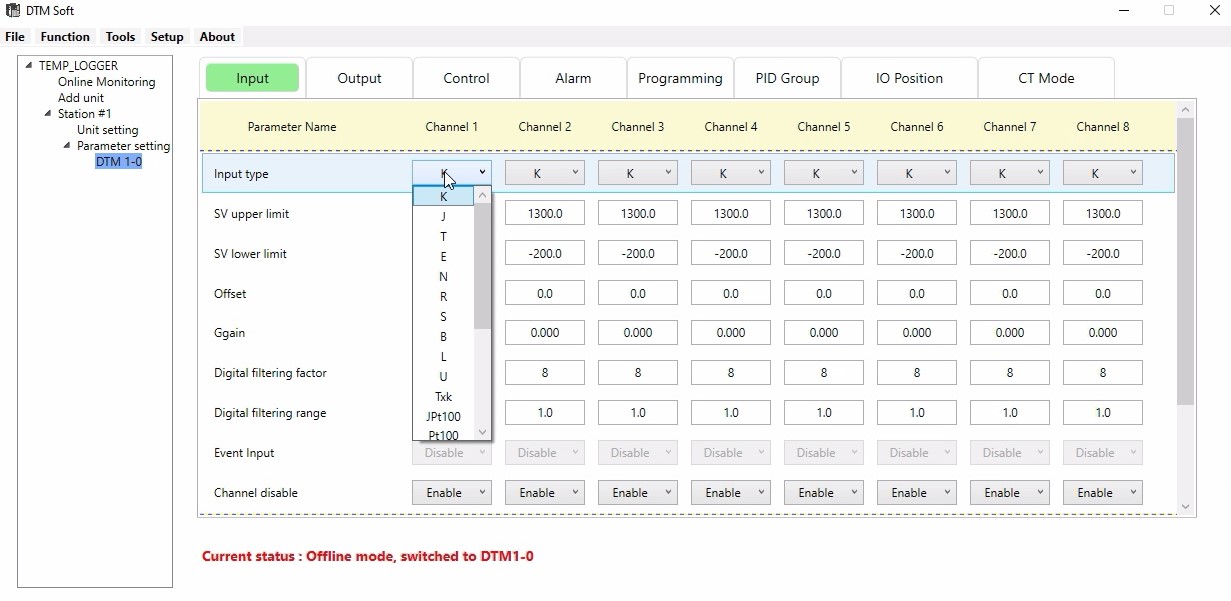

- Click on the DTM 1-0 below the parameter setting.A window opens give the input type as jPt100(for RTD) in INPUT option.(NOTE:You can select the sensor type that you have.)

- You can change the measuring range of the selected sensor corresponding to your calibration range or you can leave the universal range that is assigned during the selection of the sensor.

- Since we are using 4 channels,Enable the first 4 channels and Disable for next 4 channels.

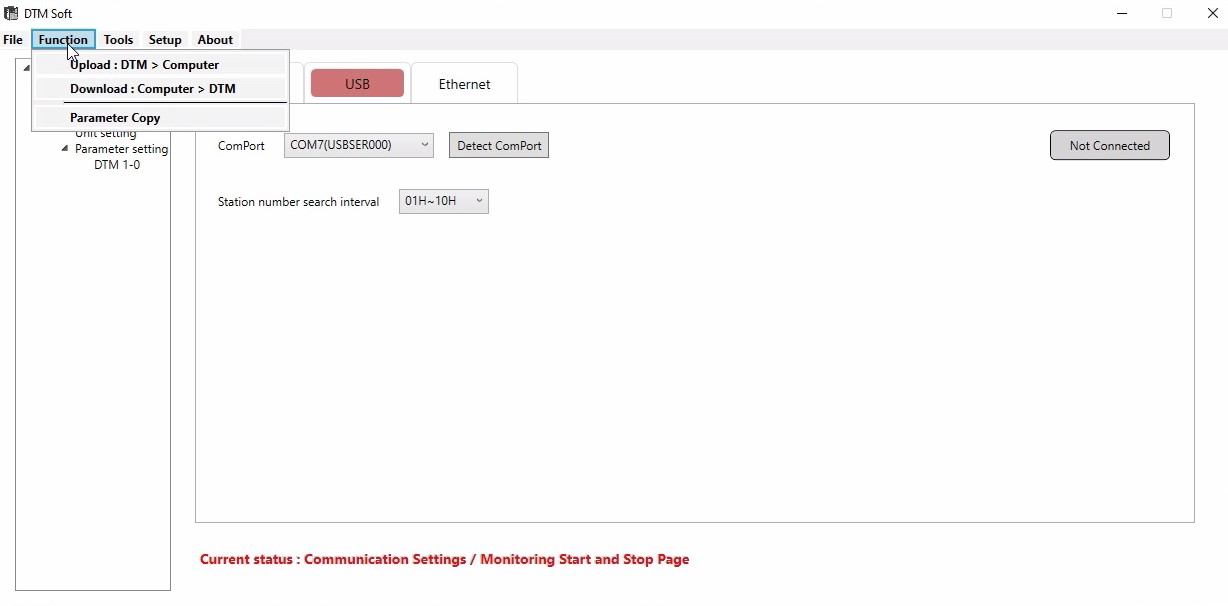

- Then go to USB option at the top, go to Function at the left corner.

- Drop down and give Download,the scanning will be processed.

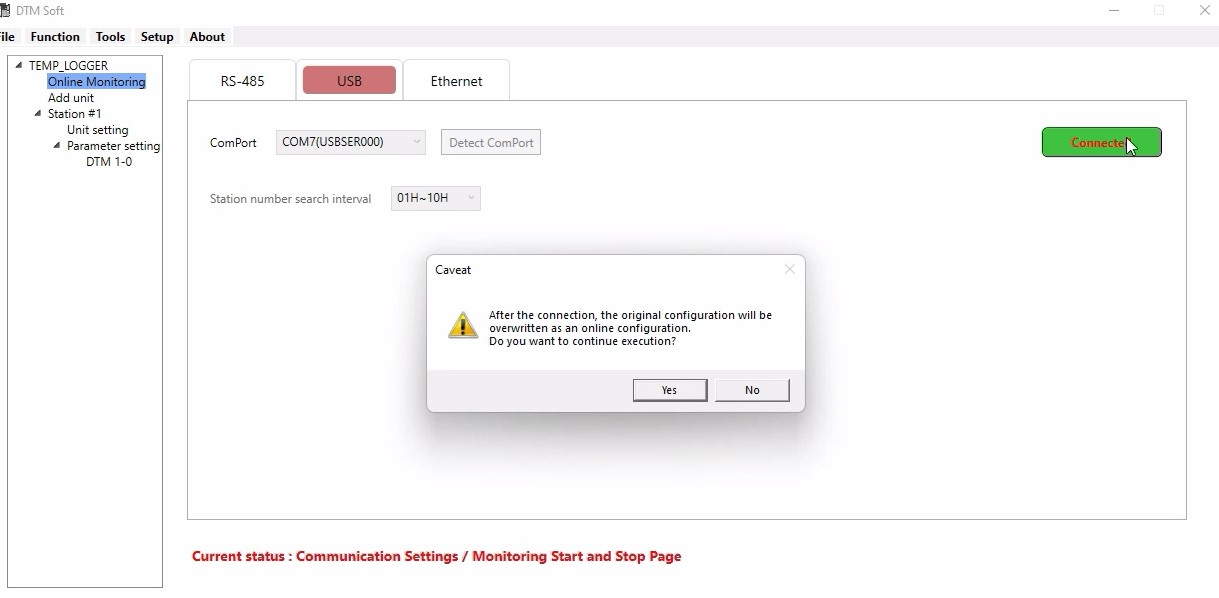

- After scanning a window will open click on the option given under Online configuration,then give OK.

- Download will be in progress.After completion give OK.

- Next click on the Not connected option on the right side,it will changeto Connected,Give yes for the popup message,and scanning will be progressing.

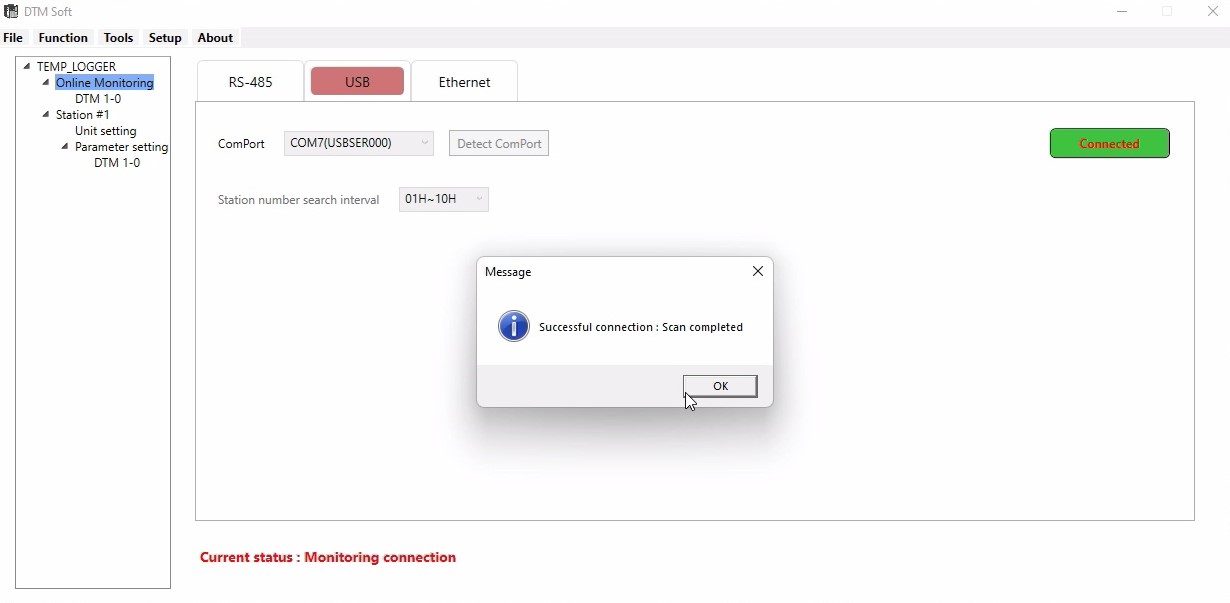

- After the scanning,the communication will be established between the PC and Scanner.

- Go to Online monitoring,click on its sub option DM 1-0,a window opens for that,there we can see the Process value of each channel.

- If the sensor is not connected to the terminals then it will shows that "sensor not connected".