- SoMachine To Citect Studio:

- Create the PLC Tags in SoMachine as Global Variables(GVL).

- Create Symbol Configuration and click the Check box in GVL to access.

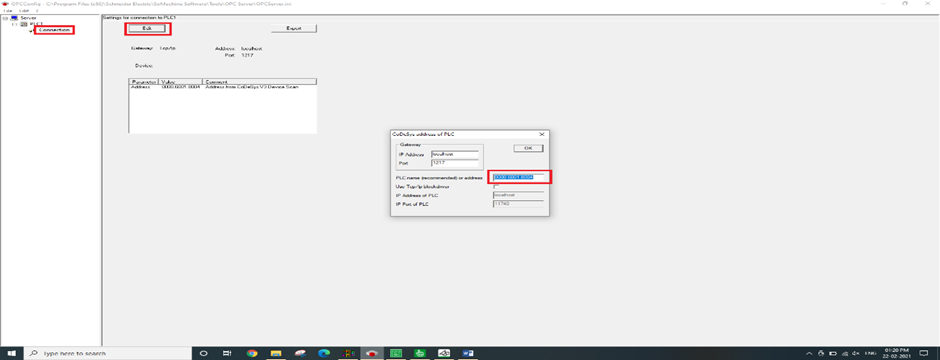

- Open OPC Server.

- Right Click Server –>Append PLC –>Click Connection –>Edit.

- Enter the PLC Name as per the SoMachine Software.

- Check the PLC Name in SoMachine –>Tools –>OPC –>CoDeSys PLC Address.

- Then save OPC Configuration.

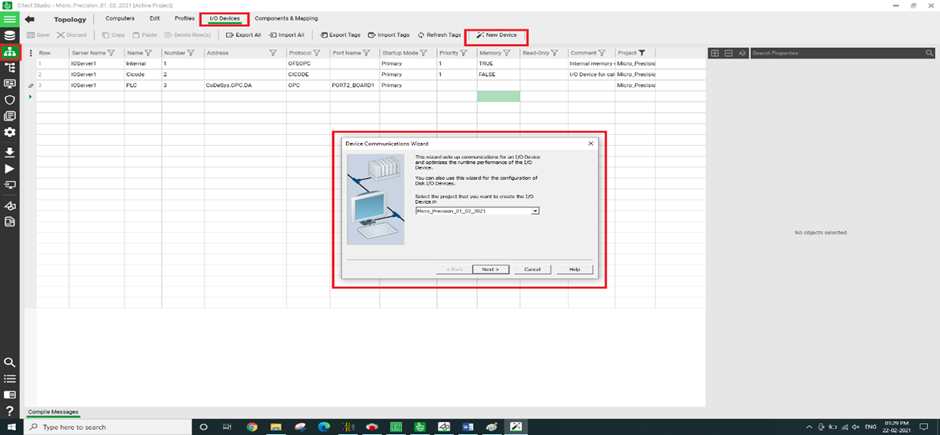

In Citect Studio:

- Open Citect Studio –>Topology –>I/O Devices –>New Device .

- Device Communication Wizard Popup Will display –>Create I/O Server –>Next

–>Create a new I/O Device–>Next –>Slecet the type of I/O Device –>Next –>Select OPC Fountation –>OPC DA Client –>OPC–>Next–>Enter the address(CoDeSys.OPC.DA)–>Next–>Click the Checkbox in the Link I/O Device to an external tag database–>Database type–>Select OPC–>External Tag Database–>OPC Data Access Server Parameter Popup Will Display–>Select CoDeSys.OPC.DA–>PLC(This is the PLC name Created in OPC server)–>OK–>Next–>Finish.

- Now the PLC Tags will connect with SCADA

- Cilck Refresh Tags for further tags added in SoMachine Software.

Welcome to Math Technologies Blog

Our Aim is “To connect the Industry – Industry – Engineer”

Why?

We are a company who is doing/providing Automation solution to the industry. That means we as a company doing projects for the industry to automate the process/machines.

What is Industry?

Manufacturing place or service providing place.

In that case we are also an industry because we are providing service to the manufacturing industry.

Why we want to connect the engineer & industry?

Because Industry own by money but run by an engineer!

Industry is a business model which aim is making money by providing Product/Service to the customers. It is done by people & Material resources.

From where we can get the people?

From where we can get material resources?

Both are important for any industry/company to do business.

We are industry we are working for an industry and the both industry need people/engineer as well material resources.

Here the place to connect Industry-Industry-Engineer

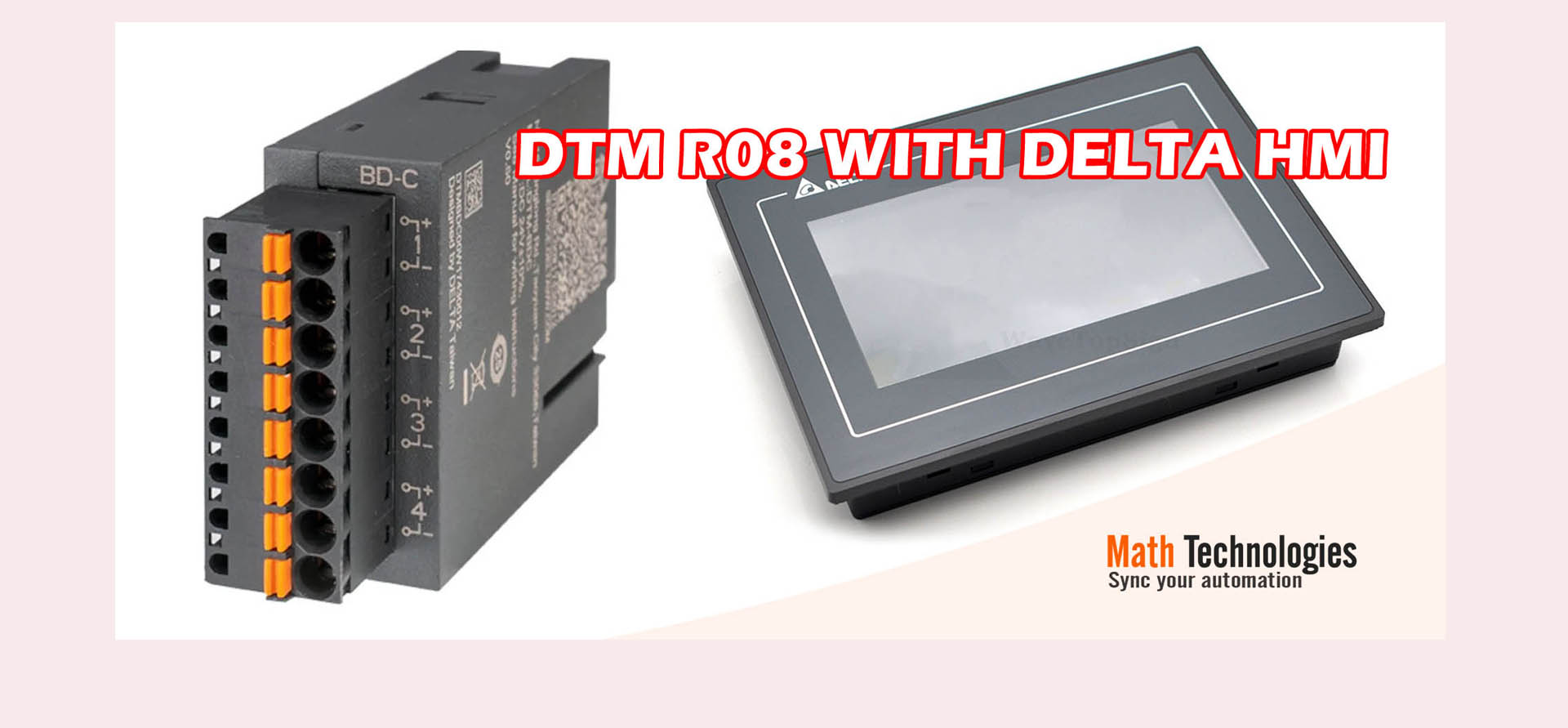

- Download DTM Soft from DELTA download center.

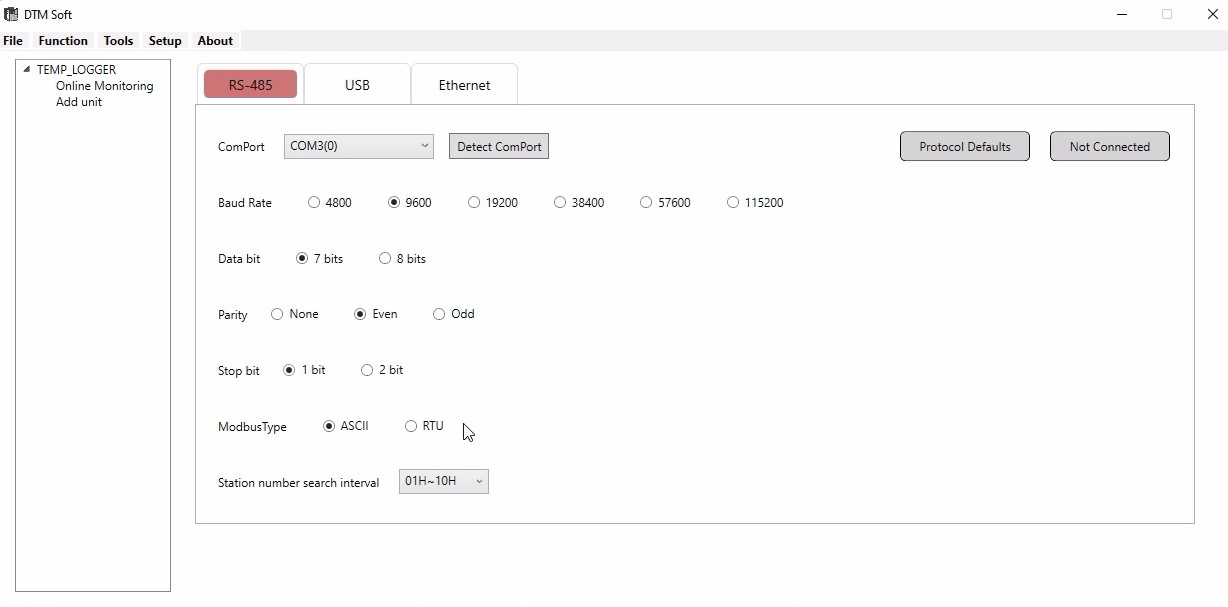

- Open DTM Soft,click New project,give Project name and save.

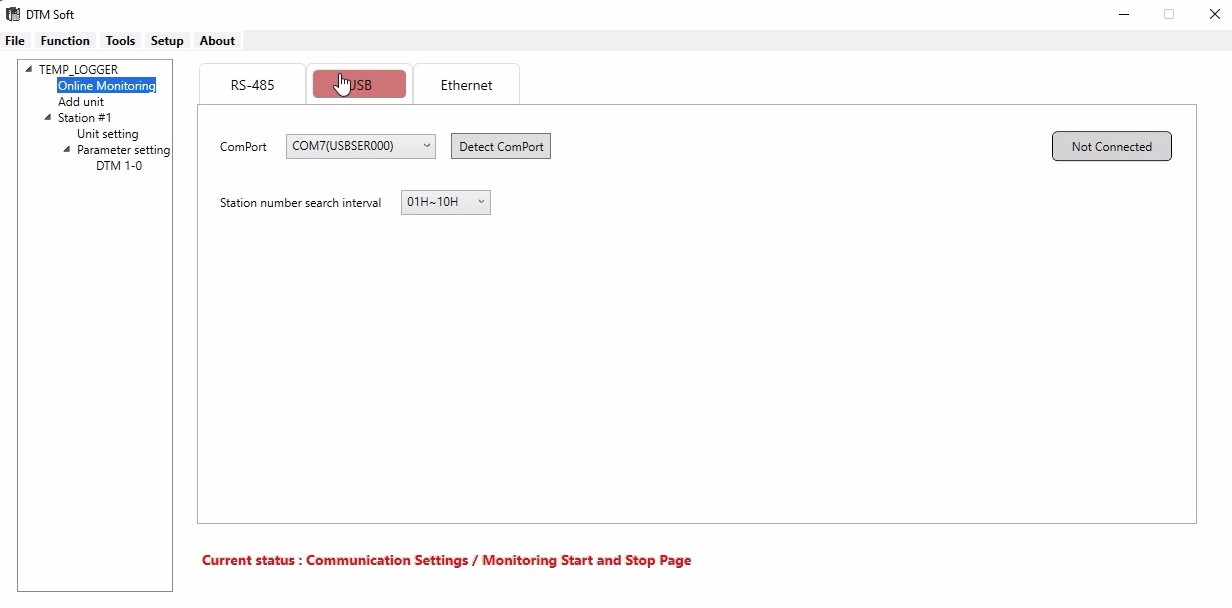

- A new window opens for the DTM Soft,click on RS 485,give com port.

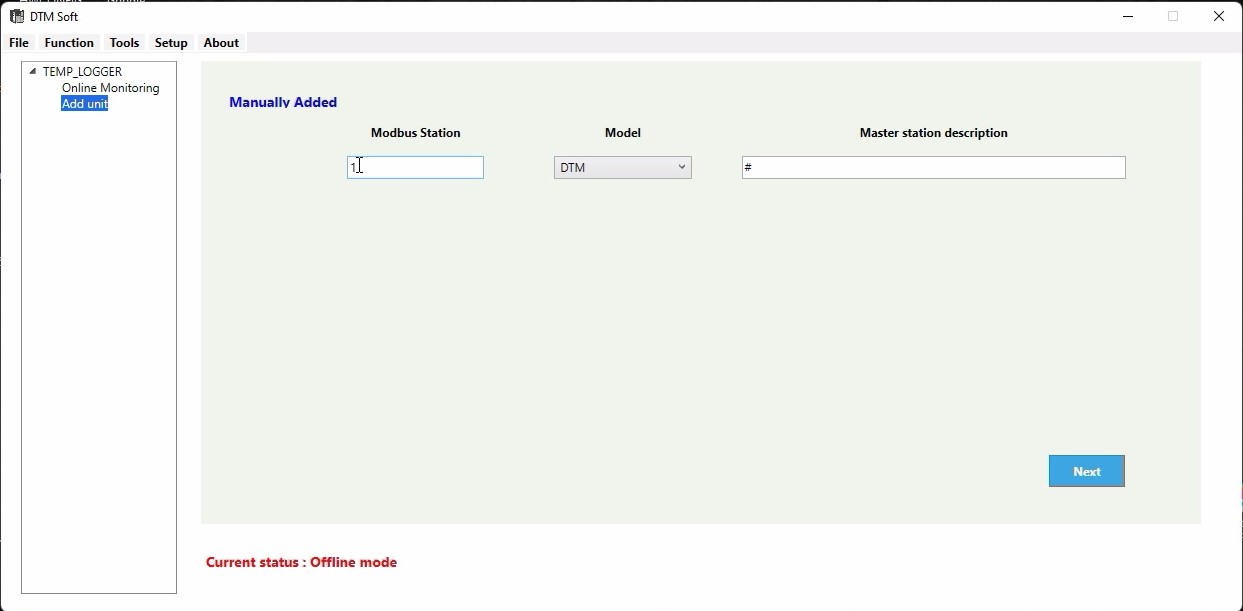

- Click Add unit on the left side,Assign modbus station number and model name,then click next.

- After giving next,a Parameter setting option will be displayed at the left side of the screen.

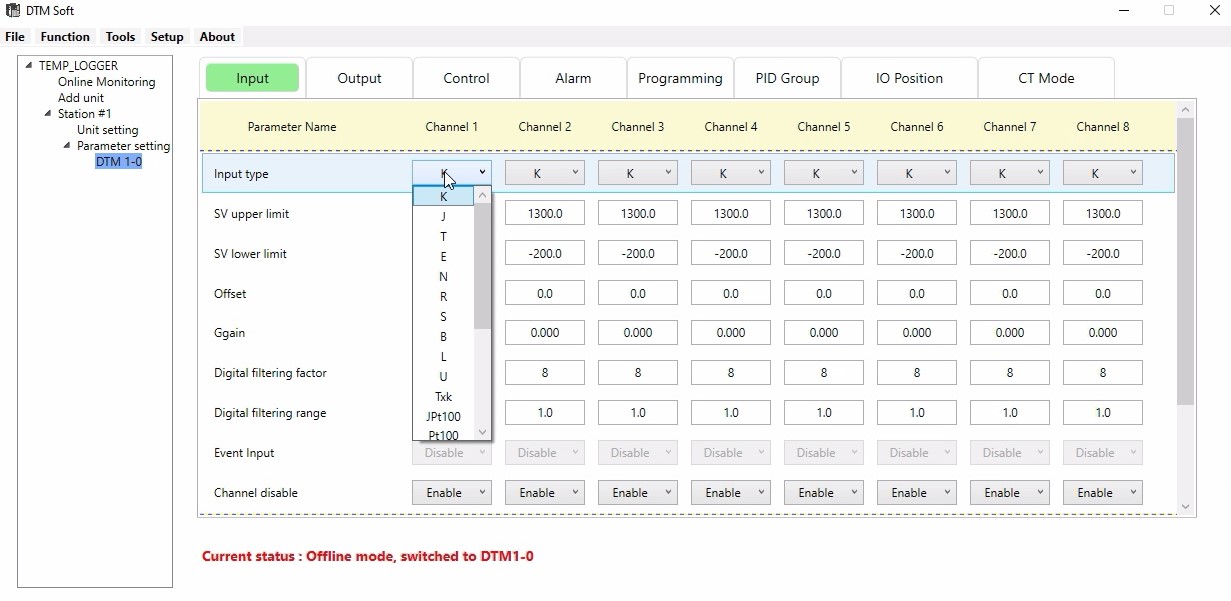

- Click on the DTM 1-0 below the parameter setting.A window opens give the input type as jPt100(for RTD) in INPUT option.(NOTE:You can select the sensor type that you have.)

- You can change the measuring range of the selected sensor corresponding to your calibration range or you can leave the universal range that is assigned during the selection of the sensor.

- Since we are using 4 channels,Enable the first 4 channels and Disable for next 4 channels.

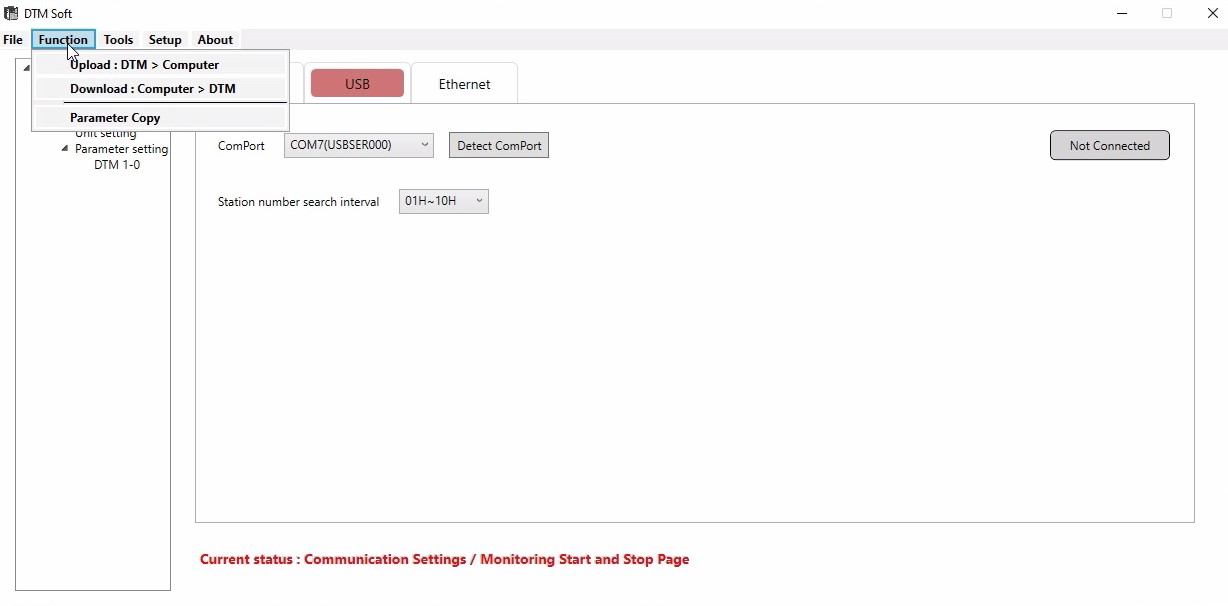

- Then go to USB option at the top, go to Function at the left corner.

- Drop down and give Download,the scanning will be processed.

- After scanning a window will open click on the option given under Online configuration,then give OK.

- Download will be in progress.After completion give OK.

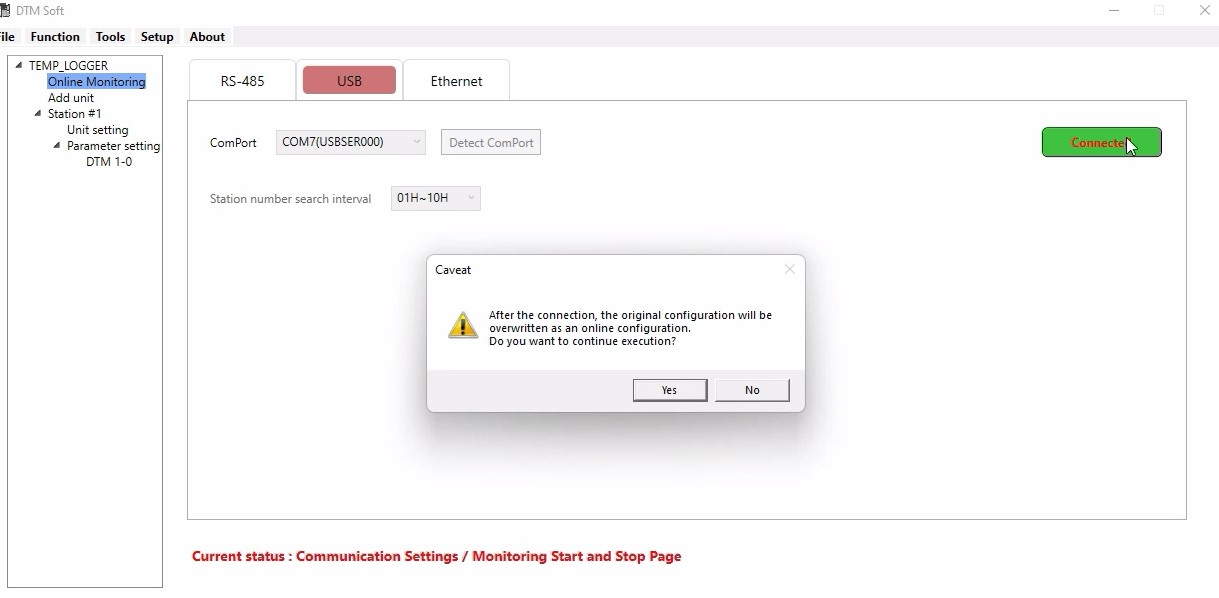

- Next click on the Not connected option on the right side,it will changeto Connected,Give yes for the popup message,and scanning will be progressing.

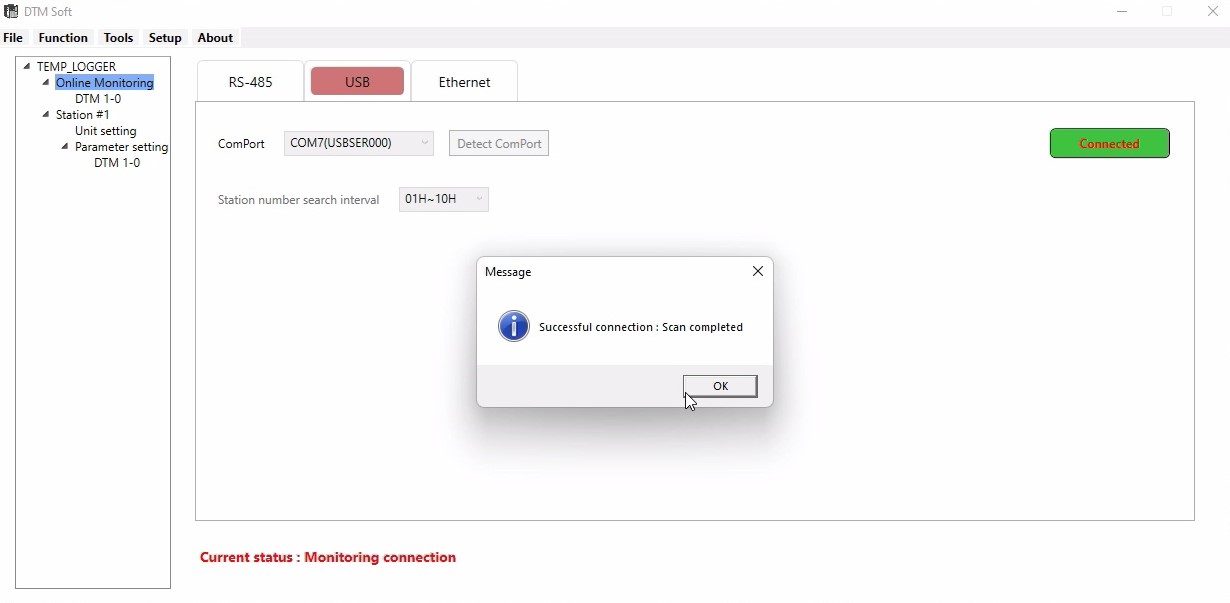

- After the scanning,the communication will be established between the PC and Scanner.

- Go to Online monitoring,click on its sub option DM 1-0,a window opens for that,there we can see the Process value of each channel.

- If the sensor is not connected to the terminals then it will shows that "sensor not connected".